Worry about the load-bearing / stability / waterproofing problems of metal roof solar bracket? You need to know this!

Worry about the load-bearing / stability / waterproofing problems of metal roof solar bracket? You need to know this!

Metal: also known as colour pressure tile, is the use of colour-coated steel plate, roll pressure cold bending into a variety of wave-shaped pressure plate, is now widely used in industrial and civil buildings, warehouses, special buildings, large-span steel structure housing roof, wall and internal and external wall decoration.

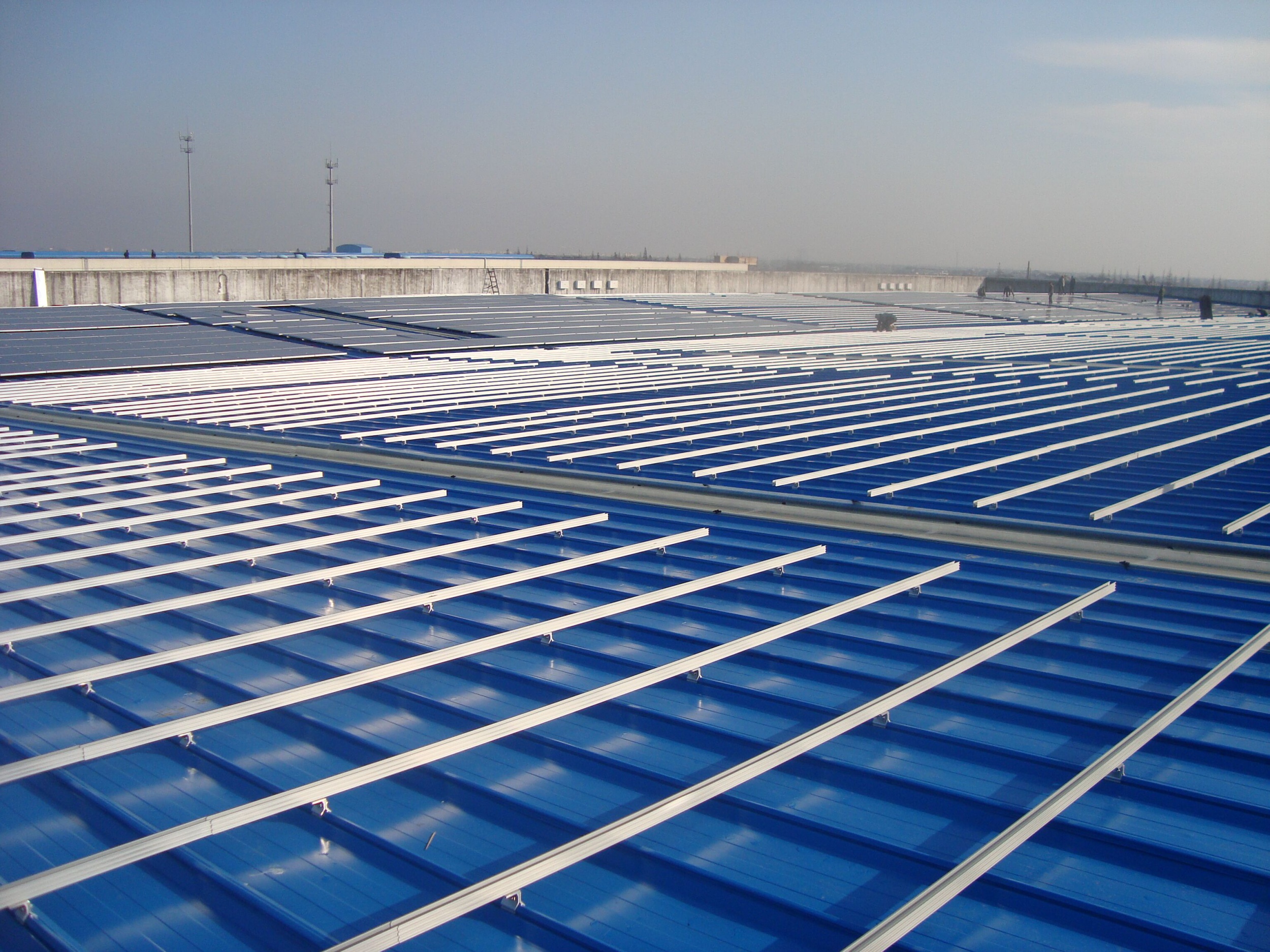

At present, the metal rooftops are mostly sloped roofs, with common slopes of 5% and 10%. The roof panel is pressure steel plate or pressure sandwich panel, and the lower part is purlin, and the purlin is built on the main support structure such as portal steel shelf. There are more examples of PV power plants installed on this type of roof. For this type of roof, the PV modules can be laid parallel along the slope of the roof, or they can be designed to be arranged in a certain inclined angle. The upper bracket can be connected to the roof bearing structure through different connectors and fasteners.

The main forms of common metal plate roof are: upright locking type,bayonet type, open stud type and so on. Different metal structure corresponds to different bracket fixture, the better the fixture matches with the metal tile, the higher the reliability of the bracket installation.

First,metal roof construction requirements

Metal roof photovoltaic power generation project belongs to the existing building metal roof transformation project, thus the building roof form, building structure form, photovoltaic array arrangement form and photovoltaic module itself, the above conditions of the diversity of the decision of the roof photovoltaic bracket form a variety of forms. The form of the roof and the structural form of the building have a greater impact on the project cost of the PV bracket. Generally speaking, the higher the waterproof grade of the roof, the roof waterproof layer is not exposed, the higher the live load of the roof and the better the overall structure of the building and the roof with strong load-bearing capacity, the lower the project cost of the PV bracket, and vice versa, the higher the project cost.

According to the structural form of the original building, roof form and bearing capacity, taking into account the actual power load and installation capacity of each workshop and other factors, the main layout of the project is: laying out along the slope of the roof, the components as the roof of the layout form, the north slope up to a certain angle, so that the layout of the north slope and the angle of the south slope is the same.

Second, different load-bearing metal roof installation method

Steel frame or roof frame, purlin and roof panel as metal roofing important components. The installation method of metal plate has important relationship with the load bearing of steel frame or roof frame, purlin and roof panel directly. The quantity and size of various connectors and fasteners can be obtained through static calculation analysis and design construction.

1、Steel frame or roof frame, purlin can meet the design requirements and roof plate steel degree is large, this way is more reasonable installation conditions, photovoltaic bracket using connectors and roof plate connection, and as close as possible to the purlin position fixed.

2、Steel frame or roof frame, purlin can meet the design requirements, but the roof plate steel degree is small, deformation is large, this type of metal roof is mainly manifested as carport, bus shelter, farms and other requirements of the degree of the place is not too high. The photovoltaic bracket can adopt the way of direct connection between the connectors and the roof panel at the purlin directly, or it can adopt the way of connection between the connectors and the purlin through the penetration of the roof panel.

3、Only the steel frame or roof frame can meet the design requirements, purlin and roof plate bearing capacity is small, this arrangement, the use of connectors and steel frame or roof frame connection, the specific connection and installation of the same bracket and purlin through the roof plate connection.

4、There is another way of connection for the position of fixed bracket roof plate cut, through the section steel column connected to the roof steel beam.

The above is the main metal roof of photovoltaic bracket arrangement way summary, for penetrating the roof of the connection, must be with waterproof gasket or sealing structural adhesive treatment, to ensure the waterproof ability. If the steel frame or roof frame, purlin and roof panel cannot meet the design requirements: the PV power station project cannot be built on the original roof. Before the design of the support, the original roof must be accurately accounted for the steel frame or roof rack, purlin, roof panel and other stress components.

Different models/arrangements/accessories should be used for different situations. If you have relevant purchasing intention, you can click “Contact Us”, and Yizhao will arrange experts to help you to choose the most suitable product.